|

Leading factory in the field of industrial automation, motor control, motion control, and energy saving: motor soft starters, power electronics, variable frequency inverter, servo... |

Water circulation pumps (water circulating pumps, circulator pumps) are typically used in circuits of heating or cooling installations in the residential and commercial applications, such as power plant, steel factory, air conditioning system.

The circulating pumps are used as centrifugal pumps.

In a centrifugal pump, the power consumed is proportional to the cube of the motor speed, while the flow rate varies in direct proportion to the speed of the pump. This means that if the motor speed, and therefore the flow rate, is reduced by half, the power consumed is reduced to one-eighth. With built-in PID feedback control, V&T EcoDriveCN® AC VFD drives are used to match the speed of a motor with a variable load.

Benefits of utilizing variable speed drives on circulating pumps:

Saves energy,

Extends motor and related machinery life,

More accurate control,

Soft starts, thus decreasing the load on the electrical network of direct starting of motors.

Some competitive advantages:

failure rate < 0.15%, similar as Siemens, Emerson Control Techniques, ABB, Danfoss, Eaton, Schneider, Allen Bradley, Lenze, Yaskawa

authorized CE by ECMG

Under the audit of NVLAP. NVLAP Lab code: 200068-0. ISO/IEC 07025:1999, ISO 9002:1994

18-month warranty period

prompt delivery lead time: 1-3 days

supply to REGAL, Ingersoll Rand, Foxconn, Tata group, L.K. Group...

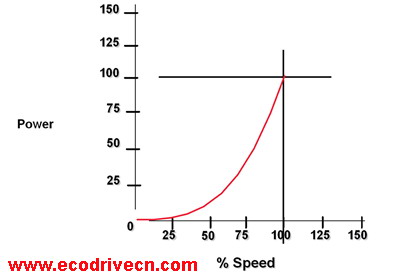

Power consumption curve of pump

V&T EcoDriveCN® AC VSD drives are widely used to save energy in pumping systems.

You may be interested in V&T EcoDriveCN® AC motor speed controllers for pumps:

PID control and vector control motor speed controllers for pumps

Enhanced Volts per Hertz control & flux vector control variable frequency drives with PID closed loop control for water circulation pumps

The circulating pumps are used as centrifugal pumps.

In a centrifugal pump, the power consumed is proportional to the cube of the motor speed, while the flow rate varies in direct proportion to the speed of the pump. This means that if the motor speed, and therefore the flow rate, is reduced by half, the power consumed is reduced to one-eighth. With built-in PID feedback control, V&T EcoDriveCN® AC VFD drives are used to match the speed of a motor with a variable load.

Benefits of utilizing variable speed drives on circulating pumps:

Saves energy,

Extends motor and related machinery life,

More accurate control,

Soft starts, thus decreasing the load on the electrical network of direct starting of motors.

Some competitive advantages:

failure rate < 0.15%, similar as Siemens, Emerson Control Techniques, ABB, Danfoss, Eaton, Schneider, Allen Bradley, Lenze, Yaskawa

authorized CE by ECMG

Under the audit of NVLAP. NVLAP Lab code: 200068-0. ISO/IEC 07025:1999, ISO 9002:1994

18-month warranty period

prompt delivery lead time: 1-3 days

supply to REGAL, Ingersoll Rand, Foxconn, Tata group, L.K. Group...

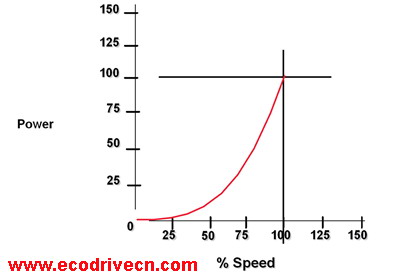

Power consumption curve of pump

V&T EcoDriveCN® AC VSD drives are widely used to save energy in pumping systems.

You may be interested in V&T EcoDriveCN® AC motor speed controllers for pumps:

PID control and vector control motor speed controllers for pumps

Enhanced Volts per Hertz control & flux vector control variable frequency drives with PID closed loop control for water circulation pumps

Photo Gallery |CE certificate |superb components

Photo Gallery |CE certificate |superb components |

| © 2016 V&T All rights reserved. |

Our Expertise & Experience Are Your Guarantee! Leading manufacturer and supplier of industrial automation, motor control and motion control. |