|

explosion proof VFD,HazLoc softstarter, motor soft starter, vector control variable speed drive (VSD, variable frequency drive, AC drive, inverter), reactor, sine wave filters, power electronics: quality as ABB, Siemens.

|

V5-JY advanced vector control drive cabinet for energy saving

Technical specification of unique and advanced vector control drive cabinet for energy conservation

|

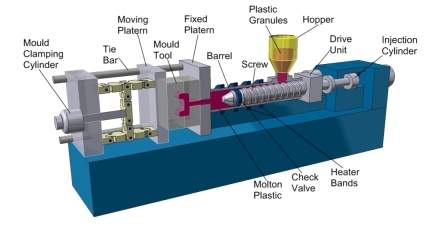

Energy efficiency retrofits of plastic injection molding machines

failure rate: < 0.15%, just the same as other world-class traditional brands, such as Siemens, ABB, Emerson, Schneider, Rockwell Automation (Allen Bradley), Lenze, Parker, Yaskawa, Mitsubishi, Omron

authorized CE, issued by ECMG

18-month warranty period

prompt delivery lead time: 1-3 days

supply to REGAL, Tata group, Ingersoll Rand, Foxconn, Tata group...

backside structure design of vector control drive cabinet, independent duct, dust-proof structure.

Radiator (heat sink), fan and filter capacitor of vector control drive cabinet can be individually cleaned and maintenance.

Voltage range:

380 VAC - 480 VAC (323 VAC - 528 VAC): 380 V, 400 V, 415 V, 440 V, 460 V, 480 V

Power range:

11kw ~ 132 kw (15hp ~ 176hp)

PID closed loop control

25% - 70% energy saving.

Easy to install, no need to change the control mode, oil and circuit structure of the original equipment.

Built-in injection molding machine energy saving interface card. Separate flow and pressure signals input, signal specifications: 0 ~ 24V / 0 ~ 2A.

Excellent current impact ability, excellent vector control characteristics guarantees a steady and continuous operation without tripping, 200% overload can run for 0.5 seconds.

Strong capability of low speed with load and fast speed adjustment ability. 180% starting torque at 0.5Hz. The acceleration is up to 0.1 seconds.

High power factor output, low reactive power losses, no large current shock when soft start.

Fast response ensures some super-precision molding processes.

Large output torque and accurate positioning under sensorless vector control mode. High performance when OEM for electric injection molding machines.

Providing customized technology curve. No need to change the drive parameters for the mold replacement, the process curve is remembered easily.

Wide range of torque output. The motor torque output is stable within the setting scope of pressure and flow, and ensures the quality of the work piece.

Adapt advanced drive mode of power module, eliminating the interference to injection molding machine control loop and sensor when the servo drive is running.

Applications:

injection molding machine, die casting machine.

Application about V&T EcoDriveCN® variable speed drives and servo drives to retrofit plastic injection molding machines (injection moulding machines)

Photo Gallery |CE certificate |superb components

Photo Gallery |CE certificate |superb components |

| © 2016 V&T All rights reserved. |

Our Expertise Is Your Guarantee!Leading manufacturer and supplier industrial automation, motor control, motion control and energy efficiency. |